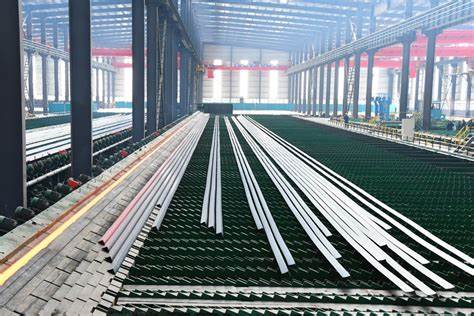

Cold Roll Forming

Raw material: Coils, Strips,Plates and other metal materials. Final product: Specific section profile as Client’s demand Machinery Application: The cold roll forming production line is customized equipment that can integrate many processes and systems required for production according to the different demands from clients, such as automatic material change system, cutting and stamping system, as well complex welding, riveting, bending, handling and packaging system etc. These systems can greatly improve production efficiency and reduce production costs.