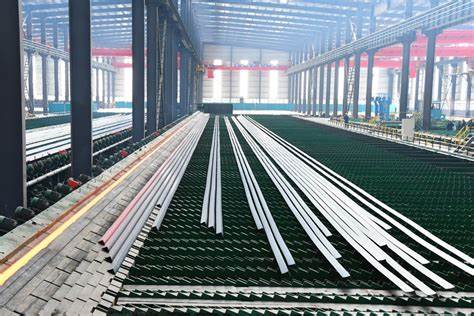

1# FLYING SHEAR

The 1# flying shear is located between the roughing mill and intermediate rolling mill. For cutting head, cutting tail of coming bar,as well accident chopping. The Technical Specification are as follows Type: crank type, start-stop working system Function: cutting head, tail and accident chopping Maximum shear section: 5160 mm2 Shearable rolling speed: 0.5~1.35m/s Shear temperature: ≥850℃ DC motor 1 set Motor model: ZTFS-355-42 Work rate: 355KW Motor speed: 500r/min