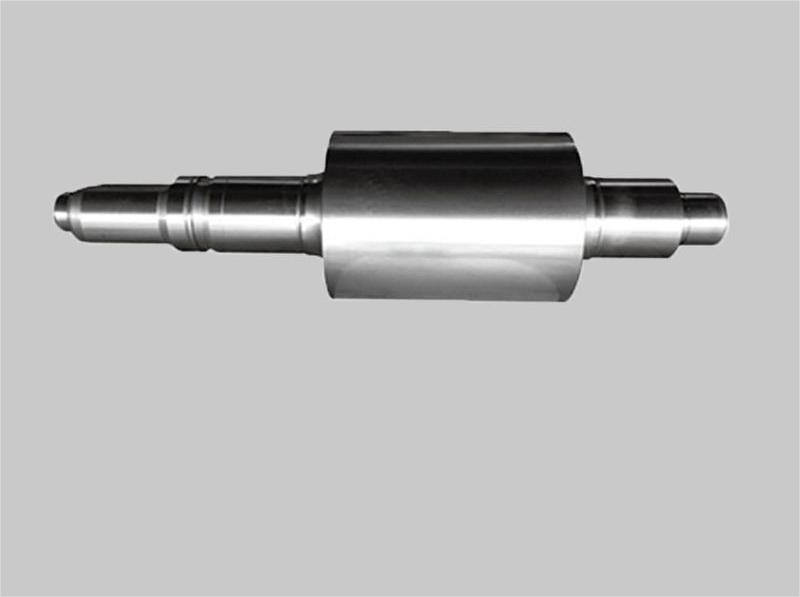

Forged Steel Rolls & Cast Steel Rolls for Rolling Mill

Product Description As the carbon content increases, the cast steel rolls can have hypoeutectoid, eutectoid or hypereutectoid structures, and their hardness increases accordingly, but the toughness and thermal crack resistance obviously decrease gradually. Cast steel rolls with eutectoid composition have better comprehensive properties of strength and toughness and are widely used in China. Alloying elements can further improve the performance of cast steel rolls. Commonly used alloying elements are chromium, molybdenum, nickel, vanadium, niobium, etc.