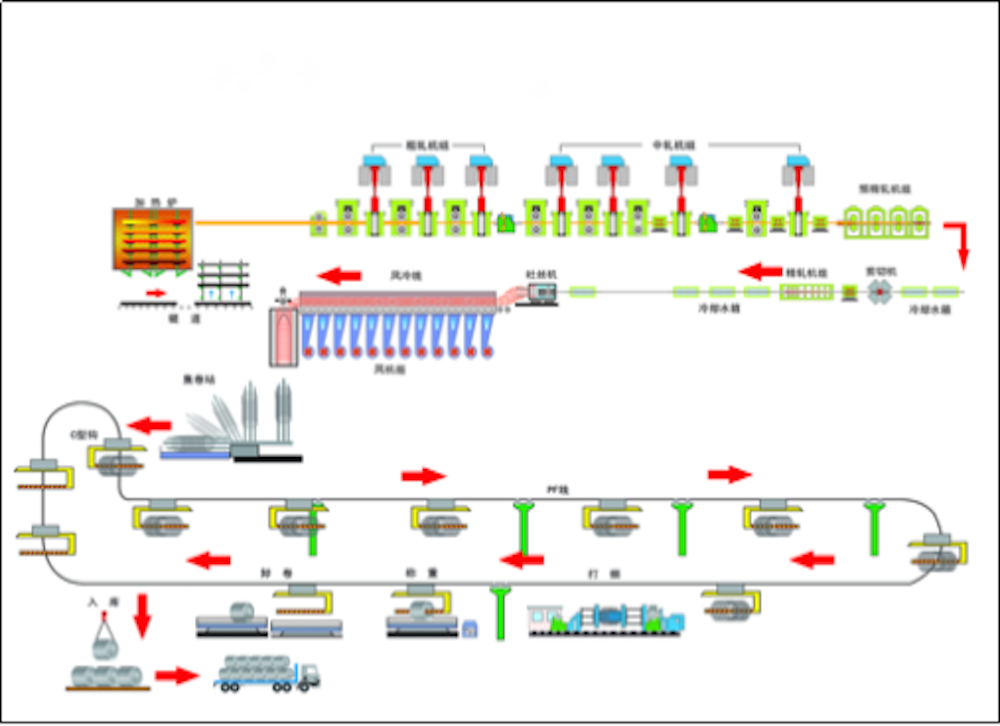

Experienced and Professional expert for hot rolling long product line,strip and flat production line. Such as bar,rebar,wire rod, section steel and strip,plate rolling mills, focus on process design, layout design, pass design and whole line technology control and improvement. Supervise and participated in hundreds of hot rolling mill design and building.

1# FLYING SHEAR

The 1# flying shear is located between the roughing mill and intermediate rolling mill. For cutting head, cutting tail of coming bar,as well accident chopping. The Technical Specification are as follows Type: crank type, start-stop working system Function: cutting head, tail and accident chopping Maximum shear section: 5160 mm2 Shearable rolling speed: 0.5~1.35m/s Shear temperature: ≥850℃ DC motor 1 set Motor model: ZTFS-355-42 Work rate: 355KW Motor speed: 500r/min